Microsoft Ranks CNC Programmers #7 in Jobs Most Affected by AI: What It Means for the Future of CNC Manufacturing

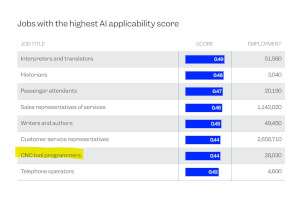

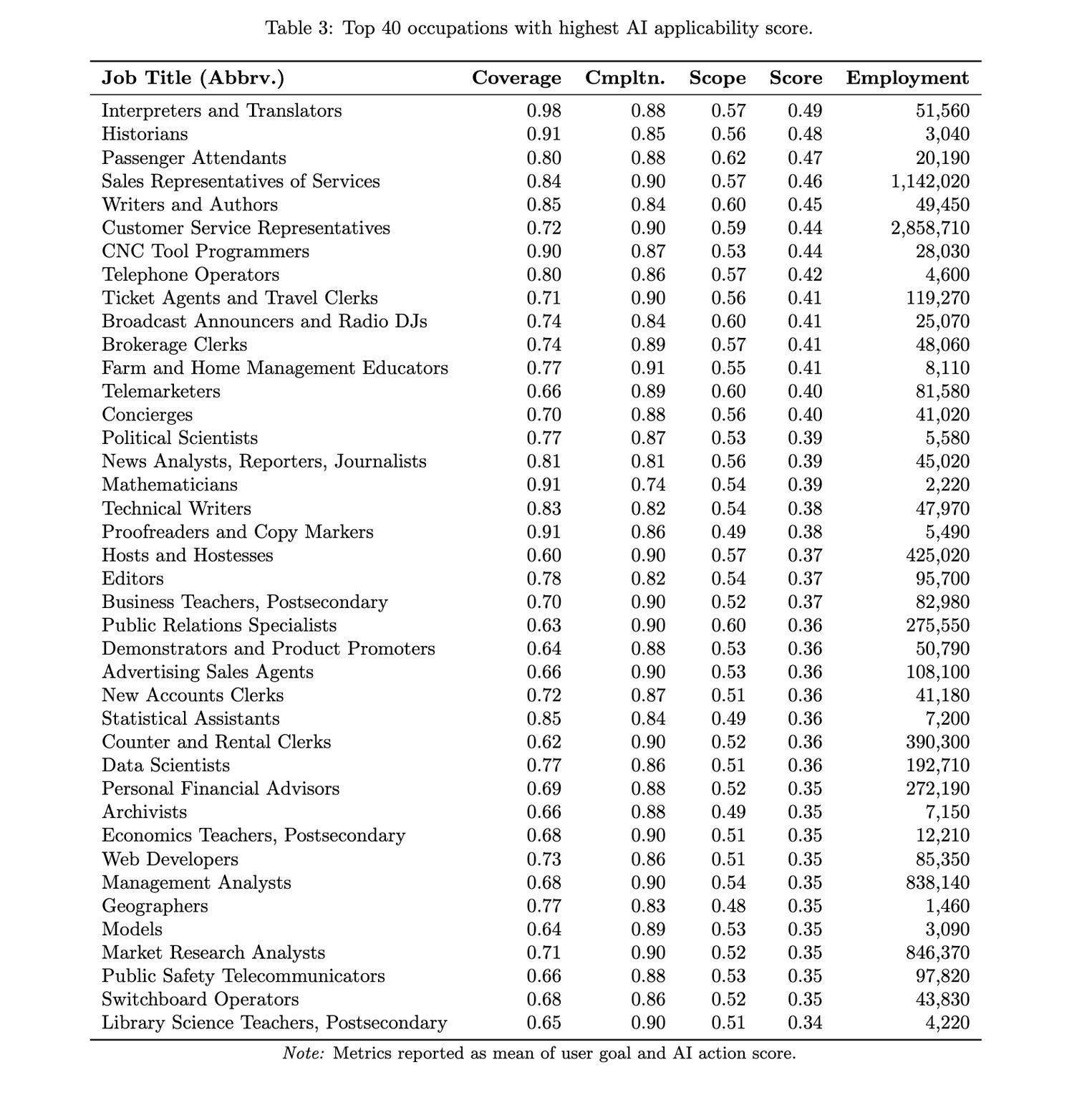

In a recent study released by Microsoft, a surprising entry appeared near the top of their list of 40 jobs most influenced by artificial intelligence: CNC Programmers ranked #7. While many might expect writers, data analysts, or customer service reps to dominate such a list, the inclusion of CNC tool programmers shows just how deeply AI is beginning to transform even the most technical and traditionally hands-on roles.

CNC Programming Meets Artificial Intelligence

CNC (Computer Numerical Control) programmers are responsible for writing the code—typically G-code or M-code—that tells machine tools how to cut, drill, and shape parts with micron-level precision. It’s a complex job that blends technical knowledge, machining expertise, and problem-solving. But as Microsoft’s Copilot AI and other large language models become more integrated into software systems, they’re beginning to play a supporting role in this process.

AI can now analyze part files, suggest tool paths, simulate cutting strategies, and even auto-generate initial code structures. Tasks that once took hours of manual coding and simulation can now be assisted—or in some cases accelerated—by AI tools trained on massive libraries of machining knowledge and best practices.

That’s why Microsoft’s study placed CNC programmers so high on the list: not because the role is disappearing, but because it’s changing rapidly with AI as a collaborative force.

The Benefits: Faster Programming, Smarter Shops

For CNC shops and manufacturers, the upside is clear. AI-assisted programming can dramatically reduce programming time, streamline setup processes, and cut down on costly human errors. With AI integration inside CAM software and cloud-based machining platforms, CNC programmers can get real-time suggestions on feed rates, tool selection, or collision risks essentially a virtual co-pilot in the programming process.

This is especially valuable in high-mix, low-volume environments where setups change frequently and programming time can become a bottleneck. AI helps standardize best practices, making it easier for newer programmers to ramp up and for seasoned pros to scale their output.

Shops that embrace AI in their workflow will likely see gains in productivity, consistency, and flexibility. And for individual programmers, this means less time grinding out lines of code and more time focused on optimization, validation, and process engineering.

The Risks: Over-Reliance and Skill Erosion

Of course, with any technological leap comes risk. One concern is that too much reliance on AI could erode the hands-on problem-solving skills that great CNC programmers develop over years of experience. When programmers stop manually optimizing toolpaths or verifying every code block, small mistakes can go unnoticed—especially if the AI is wrong, which it still can be.

Moreover, AI tools can hallucinate or misinterpret intentions, leading to inefficient or even dangerous results if human oversight is lacking. There’s also the challenge of ensuring the next generation of programmers learns the why behind the code—not just how to prompt an AI.

Companies will need to balance automation with training, making sure AI is a supplement, not a substitute, for real expertise.

The Next 10 Years: Hybrid CNC Programmers

Looking ahead, the role of CNC programmer is poised to evolve into a hybrid position—one that blends traditional machining knowledge with AI fluency. Instead of just writing code, tomorrow’s CNC programmer may spend more time reviewing AI-generated sequences, tweaking strategies for efficiency, and coordinating with robotics, simulation tools, and data analytics systems.

CAM platforms will increasingly embed AI-powered assistants that suggest operations based on part geometry, material, and machine capabilities. Simulation tools will predict tool wear or material response before the part is ever touched. And programmers will need to become comfortable managing this digital ecosystem—not just the machine itself.

For those who embrace it, the future is promising. The best CNC programmers will be in higher demand than ever, not only because they can write clean code, but because they can lead digital machining processes, validate AI outputs, and push the boundaries of what’s possible in advanced manufacturing.

CNC Isn’t Going Away, It’s Getting Smarter

Microsoft’s study doesn’t signal the end of CNC programming. On the contrary, it highlights just how critical this role is becoming in the age of intelligent automation. The job isn’t vanishing—it’s evolving. And those who evolve with it will be the ones driving the next generation of high-precision, high-efficiency, AI-enhanced manufacturing.

Whether you're a shop owner, an experienced machinist, or a student just entering the trade, now is the time to learn not just how to program a machine—but how to program with AI.

Want to future-proof your CNC career or shop?

Explore training programs, AI-integrated CAM software, and CNC automation strategies at cncmachines.com.