The Future of CNC: Humans and Machines Working in Tandem for Maximum Output and Minimum Waste

The Future of CNC: Humans and Machines Working in Tandem for Maximum Output and Minimum Waste

How real-time monitoring, AI, and human ingenuity are merging to eliminate wasted time, effort, and opportunity in manufacturing.

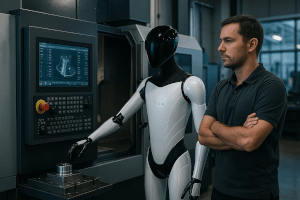

Introduction: The New Era of Human–Machine Collaboration

For decades, CNC machines have represented precision, repeatability, and productivity. Yet even the most advanced machine tools still depend on human setup, supervision, and adjustment. In 2025 and beyond, that dynamic is changing.

The modern CNC shop is evolving from operator-driven workflows to operator-optimized ecosystems, where humans and intelligent machines function in tandem. Through real-time data, AI analytics, and automated feedback loops, manufacturers are finally achieving what the industry has promised for years: Maximum output with minimum human waste — no idle machines, no idle minds.

From Automation to Collaboration: A Shift in Manufacturing Philosophy

Traditional automation focused on replacing repetitive human labor. But the next generation of smart manufacturing doesn’t remove people — it elevates them.

| Era | Role of Humans | Role of Machines | Outcome |

|---|---|---|---|

| 1980–2000 | Manual setup, supervision, maintenance | Execute pre-programmed cuts | High labor dependence |

| 2000–2010 | Automation & CNC optimization | Perform consistent operations | Better precision, but limited feedback |

| 2010–2025 | Real-time data & networked control | Sense and report conditions | Machines become self-aware |

| 2025–2035 | Human–Machine Tandem Intelligence | Humans direct strategy, AI directs motion | Full synergy, minimal waste |

This shift marks a new era: “Human-in-the-loop automation.” Humans now focus on higher-level tasks — process design, part optimization, and strategic decision-making — while AI and machine sensors handle execution, quality control, and predictive adjustments.

Real-Time Monitoring: The Heartbeat of Human–Machine Tandem Work

In the future-ready CNC environment, every spindle, axis, and toolpath generates real-time data. Using IoT sensors and machine monitoring platforms, manufacturers can now see exactly how efficiently each asset performs — instantly and continuously.

Key Metrics Driving Real-Time Synergy

- Spindle Uptime (% of time cutting vs idle)

- Cycle Efficiency (programmed vs actual runtime)

- Tool Wear & Breakage Detection

- Energy Consumption per Part

- Human Touch Time per Job

- Machine-to-Machine Communication Latency

Modern platforms like T.O.M. (Time on Machines) and other smart manufacturing systems integrate these data streams into live dashboards that empower both humans and AI to act.

“When humans and machines share the same data in real time, they stop working against each other and start working as one organism.”

The Goal: Zero Wasted Motion, Zero Wasted Mind

Wasted Human Time

Humans spend hours walking between machines, waiting for alerts, or performing checks software could automate.

➡ In the tandem model, these are eliminated.

Wasted Machine Time

Machines sit idle waiting for operators, approvals, or setups.

➡ AI scheduling, predictive maintenance, and auto-changeovers solve that.

Wasted Mental Energy

Operators often troubleshoot preventable issues due to data silos or unclear workflows.

➡ Unified dashboards and digital twins keep humans focused on improvement, not firefighting.

Every second saved per cycle compounds into exponential gains. When multiplied across hundreds of machines, it translates to millions of dollars in additional capacity per year — without adding labor or floor space.

The Technology Stack Enabling Human–Machine Harmony

| Layer | Technology | Function |

|---|---|---|

| Machine Layer | Smart CNC controllers, IIoT sensors, adaptive servo motors | Real-time condition monitoring and motion correction |

| Data Layer | Edge computing, cloud integration, MQTT brokers | Aggregates and synchronizes machine data |

| Intelligence Layer | AI algorithms for predictive maintenance, tool wear, part quality | Detects inefficiencies and suggests improvements |

| Human Interface Layer | AR dashboards, digital twins, mobile alerts | Empowers humans to make data-driven adjustments instantly |

Together, these layers form what many now call the Cognitive CNC Environment — a hybrid intelligence where humans and software cooperate seamlessly.

Case Study: A CNC Shop of the Near Future (2030 Vision)

Company: Apex Precision Manufacturing

Goal: Increase output 50% without hiring additional labor or adding machines.

Strategy: Integrate AI-driven machine monitoring and human-optimized workflow via a centralized system.

Before Implementation (2024)

- Spindle utilization: 41% average

- Human machine-walk time: 22 min/hour

- Average part deviation: 0.003" variance

After Human–Machine Tandem Optimization (2026)

- Spindle utilization: 84% average

- Human machine-walk time: 5 min/hour

- Average part deviation: 0.0007" variance

Result: 2× output, 35% less overtime, 18% energy savings.

Humans now focus on program optimization and quality assurance instead of repetitive supervision. The result is a lean, intelligent, and self-balancing system.

CNC 2030: The Human Role Reimagined

The Future CNC Operator:

- Interprets data, not dials.

- Designs workflows, not watches screens.

- Trains AI systems to adapt to new materials and tolerances.

- Leads continuous improvement teams that feed real production data back into digital simulations.

Humans are no longer the bottleneck — they’re the bridge between intent and automation.

Economic and Ethical Benefits

- Higher Throughput Without Burnout: Operators focus on creative, cognitive work while machines handle physical labor.

- Reshoring and Workforce Revitalization: Automation synergy reduces dependency on cheap labor and brings manufacturing back to U.S. soil.

- Sustainability and Energy Efficiency: Real-time optimization means less scrap, fewer reworks, and lower emissions.

- Empowered Workforce: Humans shift from task doers to system leaders — redefining manufacturing as a high-skill, high-pride profession again.

How CNC Machines Will Get There

To achieve this human-machine tandem model, the following developments are critical:

- Unified Data Protocols: Standardized machine communication (MTConnect, OPC UA) must become universal.

- AI-Powered Scheduling: Systems that anticipate workload, downtime, and tool availability in real time.

- Closed-Loop Feedback: Machines that adjust toolpath or feedrate automatically based on live cutting conditions.

- Cognitive Dashboards: Operators see priorities, anomalies, and suggestions in one intuitive interface.

- Skill Evolution Programs: Training operators as “Digital Machinists” — fluent in CNC, data, and AI.

The Vision: Humans at the Center of an Intelligent Factory

The future of CNC machining is not machine dominance — it’s machine partnership. The ideal factory is one where every piece of metal cut, every tool change, every inspection is guided by intelligence shared between human and hardware.

When this synchronization happens, the result is exponential:

- Zero downtime.

- Zero confusion.

- Zero wasted effort.

- Maximum output and pride in craft.

Conclusion: From Automation to Amplification

The future of manufacturing isn’t about replacing humans — it’s about amplifying human potential. In a world of smart factories, real-time AI, and interconnected CNC systems, the greatest resource remains the human mind — now liberated from repetition and focused on innovation.

This is not just the evolution of CNC. It’s the evolution of how humans create value.