The Rise of Hybrid CNC Machines: Combining Additive and Subtractive Manufacturing

The Rise of Hybrid CNC Machines – Combining Additive and Subtractive Manufacturing

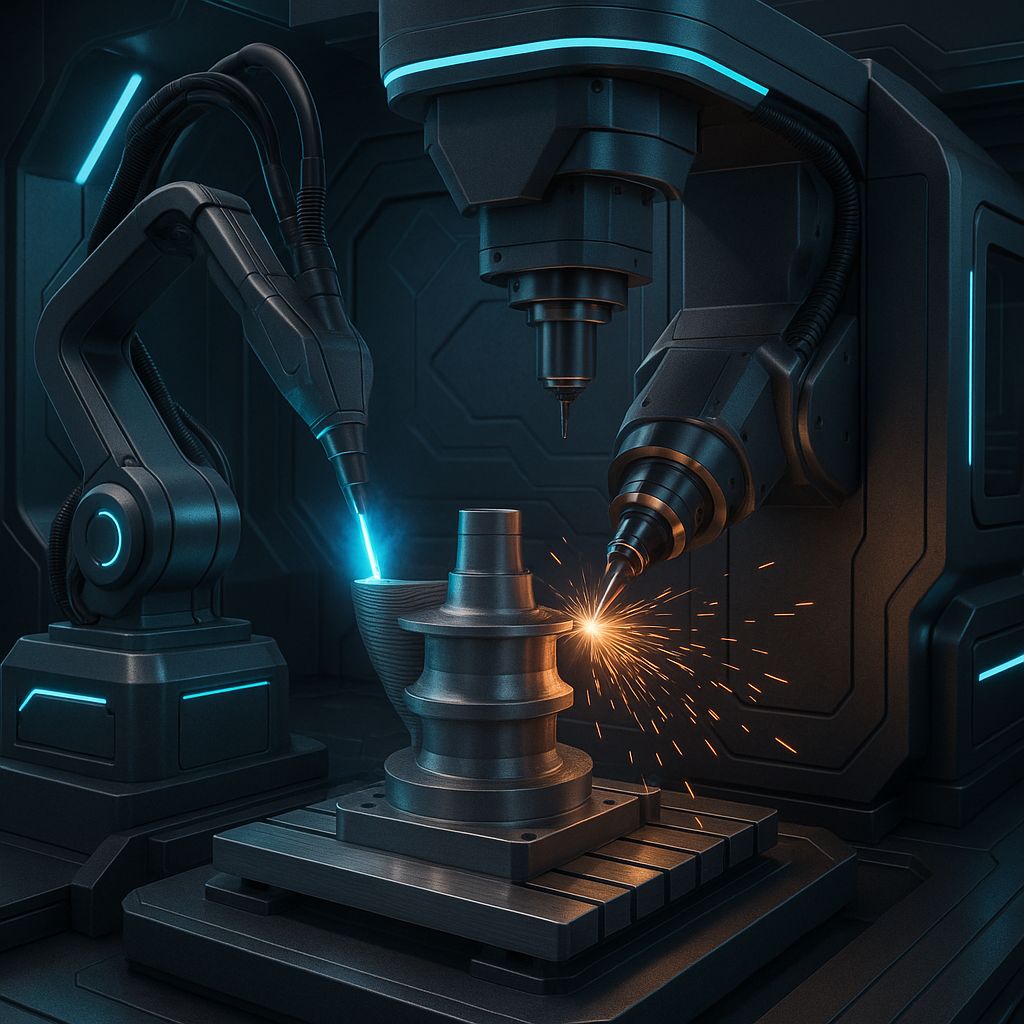

In the era of Industry 4.0, hybrid CNC machines—integrating additive (3D printing) and subtractive (CNC machining) processes—are emerging as a transformative manufacturing force. These machines offer unprecedented precision, reduced material waste, and design flexibility across diverse sectors. Here’s a deep dive into five compelling examples that illustrate this rise, enriched with future-focused perspectives.

1. Conformal Cooling Molds in Tooling & Mold Making

What’s happening: Hybrid machines blend laser metal deposition (LMD) with precision milling to create injection molds with internal conformal cooling channels. This approach delivers faster, more uniform cooling and enhances surface finish.

Why it matters:

- Reduces cycle time and enhances mold reliability

- Saves expensive materials by minimizing waste

- Enables geometries impossible with traditional machining

Future outlook: Expect this technology to extend to gas turbine blades, custom gears, and other self-cooling components. Advancements in CAM software for hybrid processes and broader integration will be key enablers.

2. Aerospace Components: Blisks & Superalloy Parts

What’s happening: Hybrid machines such as five-axis LMD plus milling systems are producing components like blisks (bladed disks) using Inconel 718 and Hastelloy® X—materials traditionally challenging due to their toughness and cost.

Why it matters:

- Cuts machining time significantly

- Reduces waste of heavy, expensive alloys

- Enables repair and additions on high-value components

Future outlook: Growth is likely in repairs (MRO), greater use of digital twins, predictive modeling of residual stresses, and comprehensive CAD/CAM integration tailored for aerospace standards.

3. Prototyping to Production: Precision with Speed

What’s happening: Hybrid CNC systems now support end-to-end manufacturing—from rapid prototyping to final precision machining—within a single workflow.

Why it matters:

- Shrinks manufacturing timelines

- Streamlines product development cycles

- Minimizes tooling costs and accelerates time to market

Future outlook: Next-gen systems may integrate real-time monitoring, AI-driven optimization, and adaptive multi-axis toolpaths to automate transitions between additive and subtractive tools.

4. Automotive, Medical, and Small Batch Production

What’s happening: Hybrid manufacturing excels in low-volume, high-complexity runs—for example, bespoke medical implants, custom automotive parts, and specialized tooling.

Why it matters:

- Supports mass customization

- Delivers fine surface quality and accurate geometries

- Allows multi-material or customized material use

Future outlook: We anticipate expanded multi-material capabilities and push toward personalized manufacturing. Intelligent planning tools will be essential to support varied material properties and production demands.

5. Smart Integration: Design, CAM, and Digital Twins

What’s happening: Software innovation is catching up with hardware: modular scripting, hybrid G‑code generation, and digital twin frameworks are emerging to streamline hybrid manufacturing workflows.

Why it matters:

- Ensures safety via toolpath collision detection

- Reduces operator complexity and errors

- Enhances control over hybrid manufacturing cycles

Future outlook: We foresee hybrid workflows fully integrated into cloud-based platforms, enabling digital manufacturing ecosystems. Designers will use topology optimization tools that automatically partition parts for hybrid sequences and generate safe, efficient toolpaths.

Summary Table: Hybrid CNC Examples & Futures

| Example | Current Use Case | Future Trend |

|---|---|---|

| Conformal Cooling Molds | Tooling with improved efficiency | CAM integration, expanded geometric complexity |

| Aerospace Components | Superalloy blisks, repairs | Predictive modeling & full hybrid toolchains |

| Prototyping to Production | Rapid prototyping + finish | AI/automation for seamless transitions |

| Customized Low-Volume Parts | Medical, automotive, bespoke parts | Multi-material hybrid fabrication |

| Smart Workflow Integration | Hybrid G-code & simulation platforms | Cloud-based hybrid CAD/CAM and digital twins |

Why This Matters & What Lies Ahead

Hybrid CNC machines represent a leap in manufacturing efficiency, sustainability, and creative potential. these keywords are essential for researchers:

- Hybrid CNC

- Additive/Subtractive Manufacturing

- Hybrid Manufacturing Trends

- Conformal Cooling

- Aerospace Hybrid Machining

- Digital Twin Manufacturing

Looking forward, the industry needs:

- Standardized hybrid CAM solutions

- Intelligent automation and closed-loop control

- Broader material compatibility (ceramics, polymers, composites)

- Workforce training in hybrid paradigms

In conclusion, with rising demand and evident success in high-performance sectors, hybrid CNC machines are not only reshaping current production; they're defining the future of advanced manufacturing.