How AI Transforms CNC: Real Case Studies on Toolpath, Maintenance & Quality

How AI Will Impact CNC Machines: A Visualized, Case-Powered Insight

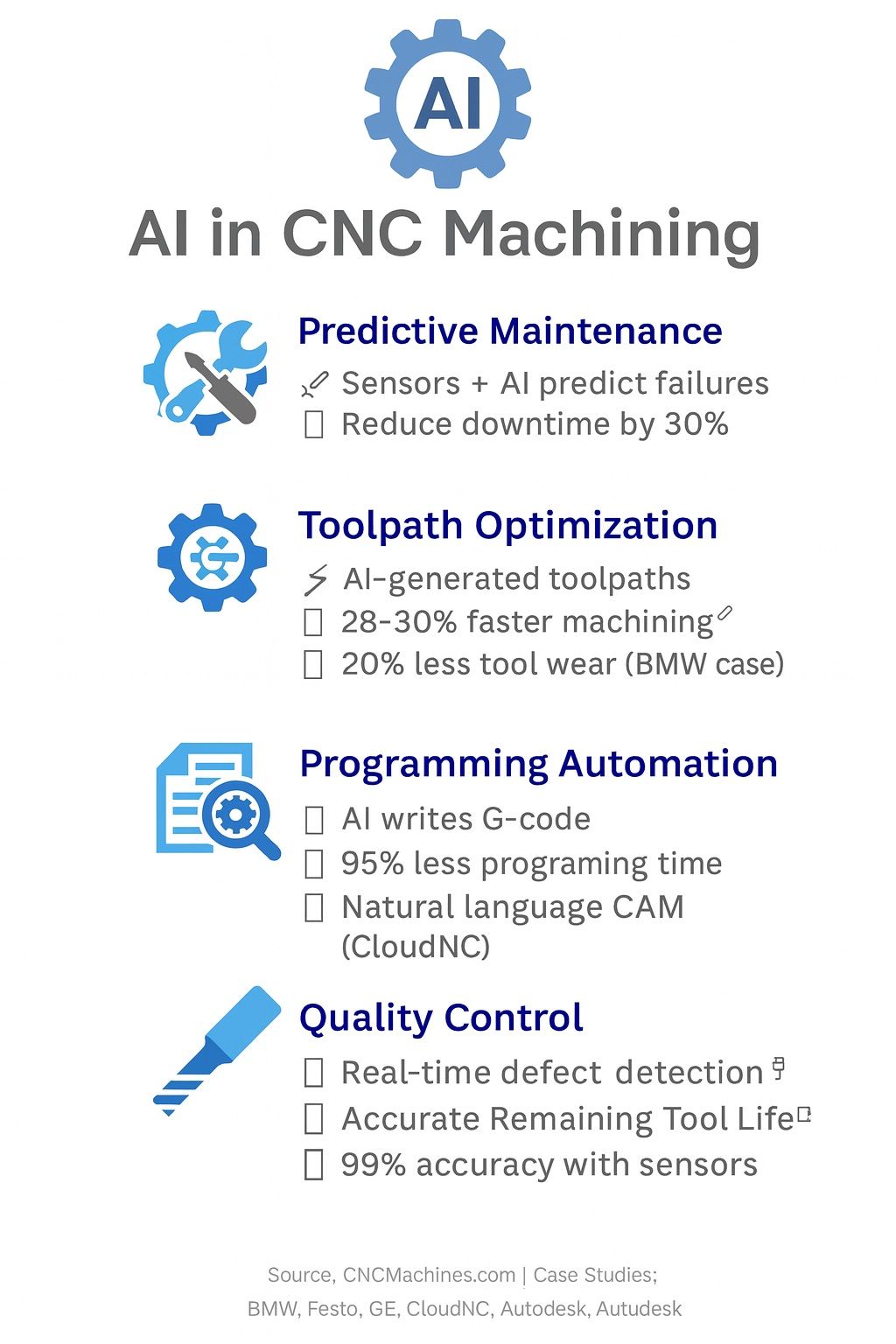

Artificial Intelligence (AI) is transforming CNC (Computer Numerical Control) machining—from intelligent toolpath optimization and predictive maintenance to real-time quality control. Below is a detailed breakdown incorporating a visual aid and real industrial case studies.

Visual Overview: AI + CNC Machining

(Above image visualizes AI integration in CNC machining—highlighting data sensors, real-time monitoring, and dynamic toolpath adjustment.)

Case Studies: Real-World AI in CNC

1. Toolpath Optimization — Aerospace Manufacturer (Fusion 360 / CAM Tools)

A mid-size aerospace parts manufacturer applied AI-powered toolpath optimization using Fusion 360. Results included:

- 28% cycle time reduction

- 40% fewer tool changes

- 15% improved surface finish

- 22% lower production costs

2. AI-Enhanced Toolpath Programming — Autodesk + CloudNC

Autodesk integrated AI with CloudNC’s CAM tools:

- Achieved up to 95% reduction in programming time

- Enabled natural language commands—e.g., “machine the top face of this part”

3. Predictive Maintenance — Festo AX (Machine Tools)

Festo’s AI-driven platform, Festo AX, helped a machine tool manufacturer:

- Detect early anomalies in tool magazine components

- Save $16,000 per machine annually

- Achieve ROI in under a year

4. Toolpath Optimization — BMW

BMW used AI for CNC toolpath optimization and gained:

- 30% reduction in machining time

- 20% decrease in tool wear

5. Predictive Quality & Maintenance — Bosch & Siemens

- Bosch reduced maintenance costs by up to 25% and downtime by nearly 30% using AI-powered predictive maintenance.

- Siemens achieved a 20% boost in machine availability and a 15% cut in maintenance costs by integrating AI into its CNC maintenance systems.

6. Jet Engine Manufacturing — GE Aviation

GE Aviation deployed AI on sensor data for predictive maintenance:

- Scheduled repairs proactively before failures

- Increased uptime and reduced emergency repair costs

Research Spotlight: Advanced AI Techniques

- Ultrasonic + CNC Tool Wear Prediction Researchers used ultrasonic microphone arrays and convolutional neural networks (CNCs) to accurately predict the Remaining Useful Life (RUL) of cutting tools.

- Single-Sensor Tool Wear Prediction A deep learning approach using just one accelerometer achieved 99.1% accuracy in identifying tool wear.

Summary Table: AI in Action

| Impact Area | AI Application | Case Study / Result |

|---|---|---|

| Toolpath Optimization | AI-enhanced CAM programming | Aerospace: 28% time cut; BMW: 30% faster, 20% less wear |

| Programming Automation | Natural language & AI assistant in CAM | Autodesk + CloudNC: 95% reduction in programming time |

| Predictive Maintenance | Sensor-based failure forecasting | Festo AX: $16,000 saved/machine; Bosch: 30% less downtime |

| Quality & Uptime | Real-time monitoring, uptime improvement | GE Aviation: fewer emergency downtime |

| Tool Wear Prediction | CNN & single-sensor predictive models | RUL accuracy high; 99.1% via accelerometer |

Final Thoughts

These visual and case-driven insights illustrate how AI adoption isn’t theoretical—it’s delivering measurable ROI across CNC operations. Whether it's transforming programming workflows, boosting maintenance efficiency, or optimizing toolpaths—AI is reshaping the manufacturing landscape.