Alloys: Definition What is an Alloy

Understanding Alloys:

What Is an Alloy?

Definition: An alloy is a mixture of two or more elements, where at least one element is a metal. Alloys are engineered to have specific properties that differ from the constituent elements, offering enhanced performance for various applications.he History of Alloys?

History: The use of alloys dates back thousands of years. The earliest known alloy, bronze, was developed around 3300 BCE during the Bronze Age. It was created by combining copper with tin, significantly improving hardness and durability over pure copper.

Synonyms: Another term for an alloy is a metallic compound or metal mix.

Composition: Alloys are composed of a base metal and one or more additional elements. These elements can be metals, non-metals, or metalloids.

Manufacturing Process: Alloys are typically made by melting the base metal and adding the desired elements. This mixture is then cooled and solidified, forming a new material with enhanced properties.

Characteristics: Alloys often exhibit improved properties such as increased strength, corrosion resistance, lighter weight, and enhanced durability compared to their constituent elements.

Color: The color of an alloy depends on its composition. For example, brass has a yellowish color due to its copper and zinc content, while steel is generally silver-gray.

Appearance: Alloys can vary widely in appearance, ranging from shiny and metallic to dull and matte finishes, depending on their composition and surface treatment.

Different Types of Alloys

- Steel:

- Composition: Iron and carbon, with possible additions of chromium, nickel, manganese, etc.

- Properties: High strength, durability, and versatility.

- Brass:

- Composition: Copper and zinc.

- Properties: Corrosion resistance, workability, and a bright yellow color.

- Bronze:

- Composition: Copper and tin, sometimes with other elements like aluminum or phosphorus.

- Properties: Hardness, resistance to corrosion and wear.

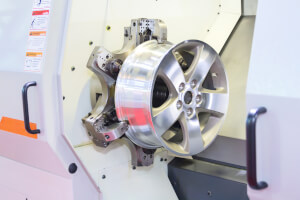

- Aluminum Alloys:

- Composition: Aluminum with elements like copper, magnesium, silicon, and zinc.

- Properties: Lightweight, strong, and resistant to corrosion.

- Titanium Alloys:

- Composition: Titanium with elements like aluminum and vanadium.

- Properties: High strength-to-weight ratio, corrosion resistance, and biocompatibility.

- Copper Alloys:

- Composition: Primarily copper, often mixed with tin, zinc, or nickel.

- Properties: Good electrical and thermal conductivity, corrosion resistance.

- Nickel Alloys:

- Composition: Nickel with elements like chromium, iron, and molybdenum.

- Properties: High temperature and corrosion resistance, excellent mechanical properties.

Physical Properties of Alloys

| Property | Description |

|---|---|

| Density | Varies depending on composition |

| Melting Point | Lower than pure metals, tailored by design |

| Hardness | Generally higher than constituent elements |

| Tensile Strength | Improved over base metals |

| Ductility | Varies, often improved flexibility |

| Electrical Conductivity | Often reduced compared to pure metals |

| Thermal Conductivity | Varies, often improved for specific applications |

Chemical Properties of Alloys

| Property | Description |

|---|---|

| Corrosion Resistance | Enhanced to prevent oxidation and degradation |

| Reactivity | Tailored to reduce unwanted reactions |

| Passivation | Ability to form protective oxide layers |

| Chemical Stability | Improved over base metals |

| Oxidation Resistance | High, especially in nickel and stainless steel alloys |

Applications of Alloys

- Construction: Steel and aluminum alloys for buildings, bridges, and infrastructure.

- Automotive: Lightweight aluminum and high-strength steel alloys for vehicle frames and components.

- Aerospace: Titanium and aluminum alloys for aircraft and spacecraft structures.

- Electronics: Copper and gold alloys for electrical components and connectors.

- Medical: Biocompatible titanium alloys for implants and surgical instruments.

- Marine: Corrosion-resistant alloys like bronze and stainless steel for ships and submarines.

Benefits of Alloys

- Enhanced Strength: Alloys are generally stronger than pure metals.

- Corrosion Resistance: Many alloys are designed to resist rust and corrosion.

- Improved Durability: Alloys tend to last longer under stress and harsh conditions.

- Cost-Effectiveness: Alloys can be more economical by combining cheaper materials to achieve desired properties.

- Versatility: Customizable properties make alloys suitable for a wide range of applications.

Alloys play a crucial role in modern manufacturing and technology, providing materials that combine the best properties of their constituent elements. From everyday items to advanced aerospace components, alloys are indispensable in achieving the performance and reliability required in today's world.

References

- ASM International

- ScienceDirect

- Materials Science and Engineering: An Introduction by William D. Callister, Jr.

- Britannica

- Metallurgy for the Non-Metallurgist by Harry Chandler.