Building a Brand Around Made-in-USA CNC Components: Marketing Strategies for OEMs and Startups

Building a Brand Around Made-in-USA CNC Components: Marketing Strategies for OEMs and Startups

As consumers and businesses increasingly seek U.S.-made products for quality assurance, shorter lead times, and ethical production standards, manufacturers offering CNC components have a prime opportunity to highlight their American manufacturing origins. For OEMs and startups, developing a strong brand centered on “Made in the USA” can drive customer trust, differentiate from offshore competition, and even command premium pricing. Below, we explore strategies to effectively market American-made CNC parts, from product packaging to social media campaigns.

Why Emphasize “Made in the USA” for CNC Components?

- Higher Perceived Quality

Domestic production often implies strict regulatory compliance, high precision, and advanced quality checks—qualities that resonate with industrial buyers and end consumers alike.

- Supply Chain Reliability

Local manufacturing means fewer disruptions, faster shipments, and direct control over processes—particularly appealing when global events cause supply volatility.

- Patriotic and Ethical Appeal

“Made in the USA” branding can garner positive sentiment, as it supports local employment and reduces carbon footprints associated with overseas transport.

1. Define Your Brand Identity

Connect CNC Craftsmanship with American Values

- Highlight Local Workforce: Show real employees operating state-of-the-art CNC machines, emphasizing their dedication, skill, and community impact.

- Regional Pride: If your CNC shop is in a region famous for manufacturing (e.g., the Rust Belt, Midwest), weave that heritage into brand storytelling.

- Quality Commitment: Position your parts as reliable, durable, and built with the same work ethic that defines American manufacturing traditions.

2. Tailor Marketing Content and Channels

A. Website and E-Commerce

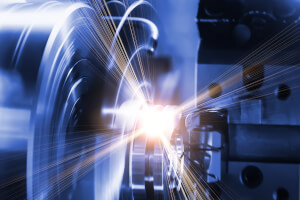

- Spotlight the Production Process: Post videos or interactive visuals of CNC milling, turning, or 5-axis machining in action, demonstrating the precision behind each part.

- Certification Badges: Display ISO, ITAR, or other relevant certifications to reinforce credibility.

- Localized SEO: Use terms like “American CNC machining,” “US-made aluminum brackets,” or “domestic contract manufacturing” to attract search traffic.

B. Social Media and Video Platforms

- Factory Tours (Livestreams / Reels): Offer behind-the-scenes snippets of milling machines, engineers calibrating jigs, or final QC inspections.

- Customer Testimonials: Share short interviews or success stories from OEMs praising the quick turnaround and high quality of American CNC components.

- LinkedIn Showcase: Post in-depth articles or industry insights, targeting professional audiences in aerospace, automotive, or medical sectors.

C. Trade Shows and Conferences

- American-Focused Booth Design: Incorporate flags, color schemes (red, white, and blue), and signage about “Made in the USA.”

- Live Demos: If space permits, bring a small CNC machine or sample parts to show real-time cutting demonstrations.

- Networking Events: Emphasize local sourcing and how it shortens supply chains during panel discussions or speaking engagements.

3. Collaborate with Industry Associations and Initiatives

Partner with Local Chambers and Manufacturing Alliances

- National Association of Manufacturers (NAM): Engage in member directories, attend events, or speak on panels about the value of U.S. CNC production.

- Regional Manufacturing Networks: Sponsor or host open-house days, allowing prospective OEM clients to see firsthand how your CNC facility operates.

Seek “Made in USA” Certification Labels

- Federal Trade Commission (FTC) Guidelines: Ensure your branding meets legal definitions for labeling products as “Made in the USA.”

- Voluntary Programs: Join industry-backed labeling initiatives that signal authenticity and compliance.

4. Build Trust Through Transparency

Showcase Material Traceability and Production Methods

- Origin of Metals: Document where aluminum, steel, or titanium is sourced—especially if it’s domestic.

- Sustainable Practices: Highlight eco-friendly solutions like recycling metal shavings or using energy-efficient CNC machines.

“Open Book” Approach

- Detailed Project Timeline: Outline each manufacturing step, from CNC programming and toolpath simulation to final inspection.

- Pricing Rationale: Emphasize that labor, local overhead, and environmental compliance in the U.S. lead to consistent quality—an assurance that justifies premium pricing for many buyers.

5. Maximize Credibility with Case Studies and Partnerships

A. Real-World Success Stories

- OEM Collaboration: Document how a partner overcame supply chain delays by switching to your American CNC facility, achieving faster turnaround and improved quality control.

- Startup Innovation: Share how an emerging company validated prototypes and ramped up production within weeks by leveraging your local CNC expertise.

B. Certification and Media Features

- Industry Publications: Secure press coverage in machining or manufacturing magazines, featuring your “Made in the USA” narrative.

- Award Submissions: Apply for manufacturing or design awards to reinforce credibility and show third-party recognition.

Top Sectors That Value Domestic CNC Machining

- Aerospace & Defense: Prefers local production due to ITAR restrictions and high safety standards.

- Medical Devices: Stringent FDA regulations encourage close oversight of the manufacturing process.

- Automotive & Motorsports: Fast prototype cycles and reliability demands can benefit from short supply chains and in-person engineering collaboration.

- Electronics & Robotics: High-value, low-volume parts requiring specialized alloys and precise tolerances.

- Luxury Consumer Goods: “Made in the USA” adds exclusivity and underscores craftsmanship.

Conclusion

Building a “Made-in-USA” identity around CNC components is more than just placing a label on your packaging—it’s a strategic promise of consistent quality, ethical labor practices, and proximity-driven service. OEMs and startups can bolster their credibility by showcasing transparent processes, leveraging American heritage, and partnering with prominent local alliances or associations. Through thoughtful content, trade show presence, and engaged social media, you can amplify your domestic production advantage, all while tapping into a market eager for precision-engineered parts crafted on American soil.