What Is a Drill and Tap Machine? A Complete Guide + Top Brands

What Is a Drill and Tap Machine? A Complete Guide + Top Brands

In precision manufacturing and metalworking, the ability to quickly and accurately create threaded holes is essential. That’s where the drill and tap machine shines—a powerful solution that combines two vital operations: drilling and tapping, all in one setup.

This article covers everything you need to know about drill and tap machines, including how they work, their applications, what to consider before buying, and the top brands trusted by manufacturers worldwide.

🛠️ What Is a Drill and Tap Machine?

A drill and tap machine is a specialized piece of equipment that:

- Drills a pilot hole in metal, plastic, or other materials

- Taps the hole to create internal threads

These machines are commonly CNC-controlled, allowing for fast, precise, and repeatable threaded hole production in a wide range of parts.

🔍 Drilling vs Tapping: What's the Difference?

- Drilling: Creates a smooth, round hole

- Tapping: Cuts threads inside the hole to accept screws or bolts

In a drill and tap machine, both processes occur automatically—saving time and eliminating setup errors.

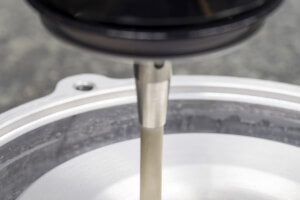

⚙️ How Drill and Tap Machines Work

The typical process:

- Step 1: The CNC program commands a drill to create a hole at a specific location.

- Step 2: The machine automatically switches to a tap tool.

- Step 3: The tap tool cuts threads inside the hole using rigid or synchronized tapping.

- Step 4: The cycle repeats across the part or batch of parts.

Some machines feature high-speed spindles, ATC (automatic tool changers), and multiple axes for complex layouts.

🧩 Types of Drill and Tap Machines

1. Manual Drill and Tap Machines

- Operator-controlled

- Best for low-volume, custom, or prototyping jobs

2. CNC Drill Tap Centers

- Fully automated

- Ideal for high-volume, production-line environments

3. Articulating Tapping Arms

- Semi-automated hand-guided tools

- Used in fabrication and light manufacturing environments

✅ Benefits of Drill and Tap Machines

| Benefit | Description |

|---|---|

| Speed & Efficiency | Combines two operations in one setup |

| High Accuracy | Maintains precise alignment between drill and tap |

| Repeatability | Perfect for production runs or tight-tolerance work |

| Versatility | Compatible with metals, plastics, and composites |

| Labor Savings | Reduces manual tool changes and setup time |

🏭 Common Applications

- Automotive: Brackets, blocks, transmission components

- Aerospace: Structural mounts, instrument housings

- Electronics: Enclosures, mounting boards

- Construction Equipment: Flanges, plates

- General Fabrication: Steel frames, cabinets, custom parts

🏆 Top Drill and Tap Machine Brands

When it comes to reliability, speed, and precision, these manufacturers lead the global market:

1. HAAS Automation (USA)

- Popular for Drill/Tap/Mill Centers like the Haas DT-1

- Known for easy programming, rigid tapping, and affordable automation

2. Brother (Japan)

- Industry leader in high-speed CNC drill/tap machines

- Models like the Brother Speedio S500X1 are renowned for rapid cycle times

3. Fanuc Robodrill (Japan)

- High-precision, fast CNC drill/tap centers

- Ideal for electronics and automotive part production

4. DMG Mori (Germany/Japan)

- Premium machines with ultra-precise drilling and tapping

- Best for aerospace, medical, and high-performance part manufacturing

📌 What to Consider When Choosing a Drill and Tap Machine

- Material Type: Harder metals require stronger, more rigid machines

- Hole Size & Depth: Ensure machine capacity matches part specs

- Production Volume: CNC models offer massive time savings in high-volume settings

- Spindle Speed & Feed Control: Impacts tapping quality and cycle time

- Tool Holding & Coolant System: Improves accuracy and tool life

🧠 Final Thoughts: Why a Drill and Tap Machine Is Essential for Modern Manufacturing

Whether you're a high-volume production shop or a growing job shop, a drill and tap machine can dramatically boost your throughput and consistency. By automating two of the most repetitive and critical steps in part production, these machines deliver both quality and speed.

Choosing a machine from a top brand like Haas, Brother, or Fanuc ensures you get the reliability, service, and performance needed to stay competitive.