Fine-Tuning Tolerances for CNC Machined Parts

Fine-Tuning Tolerances for CNC Machined Parts

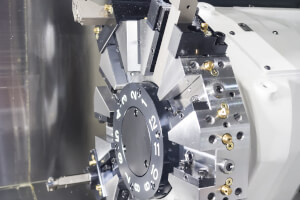

In the world of CNC machining, achieving precise tolerances is crucial for ensuring the functionality and performance of parts. Tolerances define the acceptable range of variation in a part's dimensions, which can significantly impact its fit, form, and function. Fine-tuning these tolerances can lead to better quality, reduced costs, and improved manufacturability. This article explores the importance of tolerances, offers practical tips for fine-tuning them, and provides new examples to illustrate key points.

Understanding Tolerances

Tolerances are specified to ensure that CNC machined parts meet design requirements and function correctly in their intended applications. They are typically expressed as a permissible deviation from a specified dimension, such as ±0.01 inches. Tight tolerances mean less variation, while looser tolerances allow for more variation.

The Importance of Tolerances

- Functionality and Fit: Parts with precise tolerances fit together seamlessly, ensuring proper assembly and operation. For example, a high-precision gear system requires tight tolerances to ensure smooth and efficient power transmission.

- Interchangeability: Consistent tolerances allow for the interchangeability of parts, which is vital in mass production. For instance, in the automotive industry, components like engine parts must be interchangeable to facilitate easy assembly and maintenance.

- Cost Efficiency: Tighter tolerances often require more advanced machining processes and longer production times, which can increase costs. Balancing tolerance requirements with cost considerations is essential for efficient manufacturing.

Tips for Fine-Tuning Tolerances

- Evaluate Design Requirements: Before specifying tolerances, evaluate the design requirements of your part. Consider its function, the materials used, and the manufacturing process. For example, a component subjected to high-stress environments, such as a turbine blade, may require tighter tolerances to ensure structural integrity.

- Communicate with Your Manufacturer: Collaborate with your CNC machining partner to understand their capabilities and limitations. Manufacturers can provide valuable insights into achievable tolerances based on their equipment and expertise. Open communication can help avoid unrealistic tolerance specifications that could complicate production.

- Use Geometric Dimensioning and Tolerancing (GD&T): GD&T is a standardized system for defining and communicating tolerances. It provides a clear and comprehensive way to specify the allowable variations in a part's geometry. For example, using GD&T, you can define the flatness of a surface or the concentricity of a hole, ensuring that all critical features meet design requirements.

- Prioritize Critical Dimensions: Identify the critical dimensions that directly affect the part's functionality and focus on fine-tuning their tolerances. For less critical dimensions, consider allowing looser tolerances to reduce manufacturing complexity and costs. For instance, in a mechanical linkage, the pivot points may require tight tolerances, while other features can be more lenient.

- Consider the Machining Process: Different machining processes offer varying levels of precision. For example, CNC milling and turning can achieve tighter tolerances compared to processes like laser cutting or 3D printing. Select the appropriate machining process based on the required tolerances and part complexity.

- Implement Quality Control Measures: Employ rigorous quality control measures to ensure that parts consistently meet specified tolerances. Techniques such as Coordinate Measuring Machine (CMM) inspections and Statistical Process Control (SPC) can help monitor and maintain precision throughout production.

New Examples

- Medical Implants: For medical implants like hip replacements, tight tolerances are essential to ensure a proper fit and long-term functionality. Precise machining ensures that the implant integrates seamlessly with the patient's bone structure, reducing the risk of complications.

- Aerospace Components: In aerospace applications, components such as turbine blades and engine parts must withstand extreme conditions. Tolerances must be fine-tuned to ensure optimal performance and safety. For example, turbine blades require precise dimensions to maintain aerodynamic efficiency and structural integrity under high temperatures and pressures.

- Consumer Electronics: In consumer electronics, components like smartphone casings and connectors need to fit together perfectly to ensure a sleek design and reliable performance. Fine-tuning tolerances ensures that parts assemble correctly without gaps or misalignments, enhancing the overall quality of the product.

Fine-tuning tolerances in CNC machining is a critical aspect of producing high-quality, reliable parts. By understanding the importance of tolerances, evaluating design requirements, and collaborating with manufacturers, you can achieve the right balance between precision and cost-efficiency. Implementing these tips and considering the examples provided can help you optimize your CNC machined parts for better performance and manufacturability.