What Is the F Code in CNC? Feed Rate Explained

What Is the F Code in CNC? Feed Rate Explained

If you're learning CNC programming or diving deeper into G-code, you've probably seen the F code used frequently. But what exactly does the F code in CNC mean?

In CNC machining, the F code defines the feed rate—one of the most critical parameters in ensuring accurate, efficient, and safe machining.

This article explains what the F code does, how it's used, and why it matters in your CNC programs.

⚙️ What Is the F Code in CNC?

The F in CNC programming stands for Feed Rate. It tells the machine how fast the cutting tool should move along its programmed path during a machining operation.

CNC F Code Definition:

F = Feed rate, expressed in units per minute (e.g., inches per minute or millimeters per minute)

The F code is always paired with a number, like F100, which means:

- F100 = Move at 100 inches per minute (on imperial systems)

- F250 = Move at 250 millimeters per minute (on metric systems)

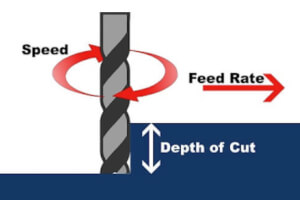

📏 Feed Rate vs. Spindle Speed

It's easy to confuse feed rate (F) with spindle speed (S), but they are very different.

- F (Feed Rate): Speed the tool travels along the workpiece

- S (Spindle Speed): Speed at which the spindle rotates (RPM)

Both are essential, but the F code controls the linear movement speed, while S controls rotational speed.

🛠️ Common Examples of F Code in CNC Programs

Here are some basic examples of the F code in real G-code snippets:

G1 X2.0 Y1.0 F150

- G1: Linear interpolation

- X2.0 Y1.0: Move to coordinates

- F150: Use a feed rate of 150 units per minute

G1 Z-1.0 F30

Move the tool downward into the material at 30 inches/min

📐 When and Where to Use F Code

The F code is typically used during:

- Milling

- Drilling

- Turning

- Tapping

- Engraving

It's most relevant when using G1 (linear move), G2/G3 (circular moves), or any cutting motion where tool movement affects material removal.

📉 What Happens If Feed Rate Is Too Fast or Too Slow?

Feed rate directly affects part quality, tool wear, and machining safety.

Too Fast:

- Tool may break

- Poor surface finish

- Machine chatter or vibration

Too Slow:

- Wasted cycle time

- Excessive tool wear from heat buildup

- Burn marks on the part (especially in wood or plastic)

💡 Pro Tip: Use Recommended Feed & Speed Charts

Always refer to the tool manufacturer’s recommendations for:

- Material type (e.g., aluminum vs. steel)

- Cutter diameter

- Depth of cut

- Type of tool (end mill, drill, insert, etc.)

Modern CAM software can also auto-generate optimal F and S codes based on tool libraries.

🧠 Summary: Why the F Code Matters in CNC

The F code in CNC machining is crucial for controlling how quickly the tool moves through material. It affects:

- Cutting efficiency

- Tool longevity

- Surface finish

- Overall part accuracy

Understanding and using the right F code ensures that your machine operates safely, efficiently, and consistently—whether you're making simple cuts or complex 5-axis parts.

🔎 FAQs About CNC F Code

Q: Do I need to re-enter F code for every move?

A: No. Once set, the feed rate stays active until changed by another F command.

Q: Can I use decimals in F code?

A: Yes, you can write feed rates like F12.5 for finer control.

Q: Is F code always in inches/minute?

A: Not necessarily—it depends on whether the program uses G20 (inches) or G21 (millimeters).